Induction Heating: Efficient Solutions for Industrial Processes

Induction heating is a contactless process that uses high-frequency alternating current to efficiently and precisely heat conductive and ferromagnetic materials. This technology has become essential across various industrial applications, offering consistent and repeatable heating for processes such as hardening, annealing, and soldering.

The Principle of Induction Heating

Induction heating operates on the principle of electromagnetic induction, where alternating current generates a magnetic field that induces eddy currents within conductive materials. These currents heat the workpiece directly, while the heating system remains largely cool. In ferromagnetic materials, additional heat is generated through magnetic hysteresis losses.

Advantages of induction technology:

- Precision: Targeted heating without direct contact.

- Energy efficiency: Improved overall energy performance.

- Flexibility: Suitable for all ferromagnetic and electrically conductive materials.

- Clean process: Emission-free and contactless, making it ideal for a variety of materials and processes, with exact control over the procedure.

- Sustainability: CO2 and emission-free heating.

Applications of Induction Heating

Induction heating is utilized in numerous industrial processes, offering precise control over energy input. It is particularly effective for:

- Hardening: Enhancing the surface hardness of metal components through quenching.

- Tempering/Annealing: Alteration of material properties through controlled heating and cooling.

- Soft and Hard Soldering: Precisely heating to melting temperatures for metallic bonding.

- Forming Processes: Heating workpieces to the optimal process temperature to alter material properties.

Thanks to its versatility, induction technology can meet even the most demanding requirements. For more details, please contact us.

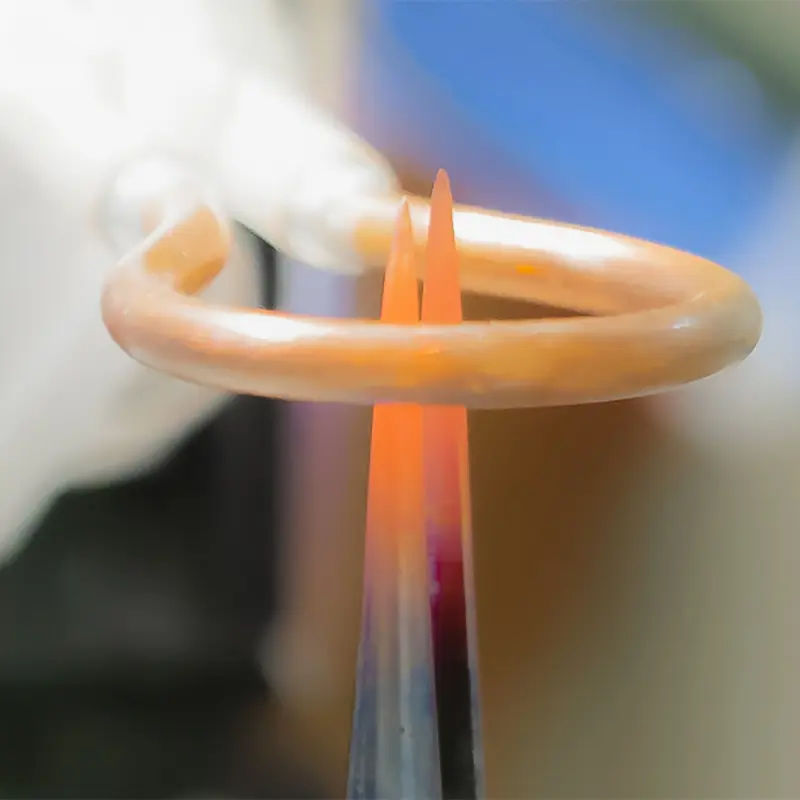

Structure and Function of an Induction Heating System

An induction heating system consists of a generator that supplies the required energy and an inductor that transfers this energy as magnetic energy to the workpiece. The inductor is a coil cooled with water. An optional control system can be added for precise temperature regulation.

Key factors depending on the application include:

- Inductor Shape: The inductor is individually designed according to the desired energy input and the process applied to the workpiece.

- Generator Power: Tuned to the workpiece and specific heating process.

- Temperature Control: Optional control systems with sensors ensure stable heating throughout the process.

Optimizing these components guarantees efficient and reliable heating results for stainless steel, aluminum, brass, and other electrically conductive and ferromagnetic materials.

Calculating and Optimizing Induction Heating

Determining the energy requirements for induction heating is crucial when designing an induction system. Factors such as material type, frequency range, and power must be precisely coordinated. With modern semiconductor technology and user-friendly controls, even complex processes can be efficiently planned and executed.

If you’re interested in integrating our induction systems into your production process, we are your reliable partner, offering comprehensive solutions and expertise.

Advantages of Partnering with H. Sigrist & Partner AG

We provide high-quality induction systems optimized for a wide range of applications. In collaboration with our partner CEIA, we ensure innovative and dependable solutions tailored to your specific needs.

Contact us today to learn more about how our technology can enhance your industrial processes.

Contact us or take a look at our downloads section.